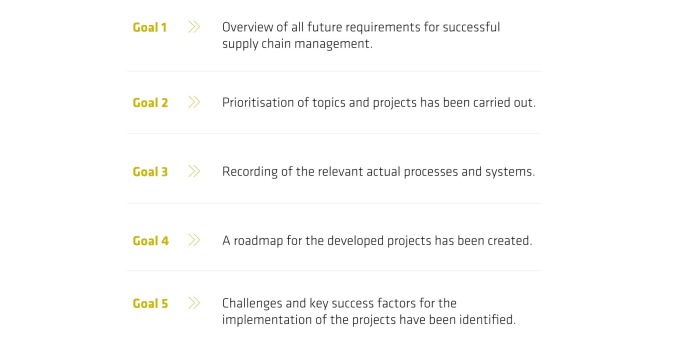

We know and understand all aspects of supply chain management, from (raw) material requirements planning, procurement, supplier integration, intralogistics and production to the operation of the developed solutions, and can help you overcome the challenges facing your supply chain:

- Heterogeneous IT landscape: siloed systems lead to data inconsistencies and add complexity to planning processes; no single point of truth

- Lack of transparency regarding the whereabouts of goods and shipments

- Information not recorded by a system, be that from physical documents, telephone conversations and so forth, resulting in a lot time spent in coordination and communication

- Time lost because you have to clear up issues if information and data is not available in the system

- Supply chain management in part done manually/subject to disruptions

- Problems exacerbated by limited resources available (chips, for example)

- Setting up a digital supply chain

- Sustainability

- Effective monitoring and efficient management

We help you overcome these challenges and set up a proactive management system.