Digital production

Taking productivity to the next level with end-to-end information flows and intelligent algorithms

Our solutions to meet your individual challenges in a digitalisation project

While every manufacturing company faces its own unique set of challenges, they often have to deal with the same types of problem:

- There are a number of digitalisation projects in production but no holistic strategy.

- Process, machine or sensor data is still not available for analyses or control tasks.

- Sufficient data is available, but it takes a lot of time and effort to analyse it because the data is stored in different systems.

- The software does not optimally support production processes, meaning additional manual work is often necessary.

- New software is needed for a new factory or a new production area.

- The software is outdated and does not provide the support employees need.

- Improvements in terms of productivity and/or sustainability are needed.

- Cooperation between production and IT must be streamlined and made more efficient.

No matter what challenges or problems your company is facing, adesso is there for you as your competent partner. Our experts develop the right solution to meet your specific situation.

We accompany you in production and logistics from the digitalisation strategy to the data infrastructure to the implementation of concrete solutions to improve value-adding processes.

Production professionals should focus on production, not on software

Our vision is that your employees in production can only concentrate on their actual tasks and use their creativity to solve complex tasks. Our software supports your employees, makes the appropriate suggestions for solutions and provides the right information. You no longer need to deal with software - we take care of that!

Software and production are where we shine

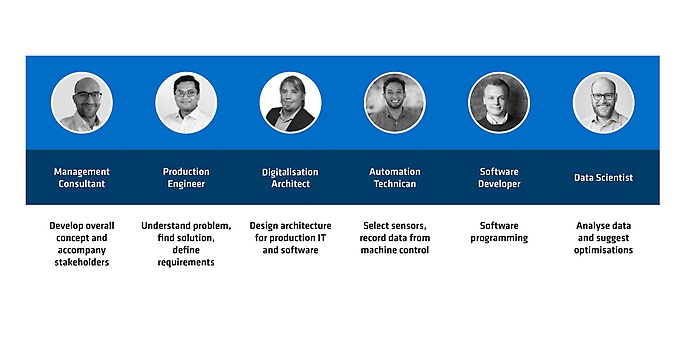

But how is that supposed to work? Quite simply, we understand that digitalisation in production requires more than just software skills. It only works if people with different skills work together as a team. That is why we solve your individual challenges in interdisciplinary teams.

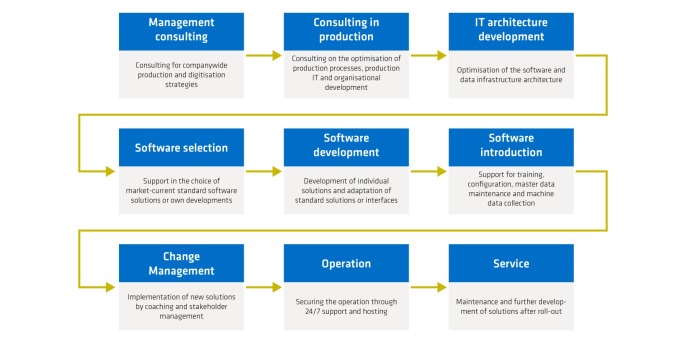

We are a one-stop provider, offering a full range of services from strategy to implementation and operation

Whether you are talking about the development of a specific use case or support throughout all phases of a digitalisation project, adesso is the right partner to have at your side.

We offer technology-neutral advice and use existing platform or framework strategies or, if necessary, we will develop custom software for you. This allows us to provide solutions that meet your exact needs and offer excellent value for your money. Our team of experts gets to work quickly to create streamlined solutions that generate clear added value. We are open to all technologies and support you in selecting the appropriate industry software, be that an MES system or an IIoT platform.

Your company specifies the technical configuration as the basis for end-to-end networking and data-driven optimisation. Whether you are talking about a local, hybrid or cloud solution integrated into an MES, ERP or other IT system, we work with you to design targeted, scalable solutions and architectures based on your specific requirements.

The future of quality assurance in the automotive industry

Quality controls play a decisive role in automobile production. This is the only way to satisfy customers, meet legal requirements and ultimately achieve economic success. However, many production processes are based on outdated systems. These often run slowly and thus impair action management. In our use case you will learn how things can run better.

Smart factory @ adesso: use cases for an efficient, digital factory

People often ask us how we would define a smart factory and what type of projects we have completed to date in this area. For us, a smart factory is not a dark factory where people no longer work. It is a factory where software supports employees in completing their work more efficiently. We believe that it is essential to have a clear roadmap, the right IT architecture and the right software (an MES system, an IoT platform or an ERP system, for example). In this way, (individual) use cases can be implemented that deliver measurable process improvements.

IIoT, digital twins, security and sustainability are the topics currently on the minds of manufacturing companies

Due to challenges caused by the climate and energy crisis as well as higher purchase prices, for example, many of our customers are focusing on the following:

An IIoT platform is the central system for the collection, storage and provision of historical and other data. The possibilities it creates range from ad-hoc analyses for direct control to forecasts of future process conditions. IIoT platforms are central to a reduction of the use of resources, especially energy.

In our free whitepaper, you can find out where companies deploy IIoT platforms, what platforms are available, how to find the right one that suits your needs and what role IIoT platforms will play in production in future.

The digital twin is closely related to IIoT. The term refers to the digital image of physical assets such as machines or products. The digital twin may contain geometry, kinematic or logic data and does not need to be a monolithic data model. It might consist of different sub-models, each of which has been developed for a specific use case. Examples of this include the ability to self-describe machines in order to be able to use them quickly for new manufacturing tasks or the simulation – that is, virtual commissioning – of new products or machines.

At the moment, we are implementing a digital twin with the aid of an asset administration shell for a major electrical engineering group. Would you like to learn more about the project? If so, please get in touch with us.

Even if the pros of digital technologies like IIoT or digital twins outweigh the cons, the risk of cyber-attacks also grows as networking increases. Attacks on industrial automation systems in particular have gone up rapidly in recent times. However, this does not mean that companies are defenceless against these attacks or have to forego the advantages of digitalisation. In fact, they should be on the constant lookout for vulnerabilities, have a security concept in place and adopt the latest cybersecurity practices.

Find out more about security services and our solutions for tomorrow’s IT. Our security experts are there to answer your questions.

Many manufacturing companies are now focusing on sustainability. That is not just because of the energy crisis, but also because the effects of climate change are increasingly being felt. Humans and the environment are reaching their limits. The manufacturing industry is aware of its responsibility and is looking for ways to make production more sustainable. We firmly believe that this can only be achieved with the help of digital technologies because they are essential to revealing the possibilities available to conserve resources.

We help you create sustainability concepts and develop software-based measurement and optimisation solutions. Find out more about our digital sustainability solutions. Get in touch with us.

Successful projects – satisfied customers A selection of our testimonials

Our testimonials give you an initial insight into our work, where we support customers in optimising their manufacturing processes with the aid of cutting-edge technologies. Our satisfied customers include Trilux, Ecoclean and Festool.

Project example 1 - Production control software (MES) for the electric powertrain and battery production of a leading German premium manufacturer

The industrial revolution is also in full swing in the automotive sector and offers radical new potential for process optimisation and cost reduction in production. Manufacturing Execution Systems (MES) and their embedding in the digital infrastructure set the course for the success of digital transformation and the Smart Factory. The requirements for a production-critical MES are clear: transparency, flexibility in configuration, process automation as well as error-free and stable production processes of aggregates.

The modular structure via microservices in a scalable and intelligent hybrid cloud infrastructure makes it possible to successfully meet the customer's requirements at several international production sites in the powertrain segment. A particular challenge on the way to fail-safe production is the dynamic exchange of data via interfaces with surrounding ERP and production facilities. For the development of this production-critical system, adesso relies on an internationally operating team of experts that combines business and methodological competence at a high level.

Project example 2 - Planning a smart factory for the production of battery storage units

Our experts demonstrate that we are not only capable of software, but also of production in an exciting project in which we are planning a smart factory for battery storage units. In the process, we are supporting our client in the selection of the location, the design of the factory layout, the planning of the manufacturing systems, the definition of the processes, the planning of the ERP and MES system as well as the IIoT platform. As our client has so far mainly manufactured single pieces in an engineer-to-order approach, they benefit from our experience in large-scale industrial production. Since the product itself is still under development, we plan the manufacturing and IT in a simultaneous engineering approach. Would you like to learn more about this project? Feel free to contact us.

Other projects where our solutions minimise waste in the production environment:

Free whitepaper: How companies can identify sustainable optimisation potential with IIoT platforms

You want to optimise your production based on data, but you don't want to have to collect the data from different software systems and databases? You don't want to have to ask a specialist for every data query? This should be a common practice in companies. But it often isn't.

In our free white paper, you can find out what companies use IIoT platforms for, which platforms are available, how to find the right one for your purposes and what role IIoT platforms will play in production in the future.

Do you have any questions?

No website and no brochure can replace a personal conversation about your goals and your issues. We look forward to an appointment with you on site.

Head of Competence Center Production Dr Patrick Kübler +49 152 38856276 patrick.kuebler@adesso.de